- Two independently adjustable TrueFocus ion sources with independently adjustable beam diameters

- High-energy operation for rapid milling; low-energy operation for sample polishing

- Adjustable milling angle range of 0° to 10°

- Sample rocking or rotation

- Microscope and camera options

Consistently produces high-quality SEM samples

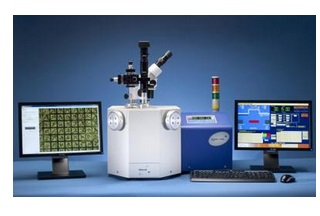

The SEM Mill is an excellent tool for creating the sample surface characteristics needed for scanning electron microscopy (SEM) imaging and analysis. The Model 1060 incorporates two independently adjustable TrueFocus (patent pending) ion sources, automatic gas control, and an oil-free vacuum system for ultra-clean processing.

Sample management

The SEM Mill accommodates a wide range of sample sizes and configurations for applications such as bulk milling, electron backscatter diffraction, and semiconductor preparation, as well as traditional slope cutting and cross-section polishing. The SEM Mill features a vacuum load lock for extremely rapid sample exchange. Once the sample is placed onto the stage, evacuation of the load lock occurs within a few seconds. Before milling, an automatic height sensing system provides feedback to a mechanical elevator so that the sample's top surface is properly aligned with respect to the ion beams. Tilt angles are continuously adjustable in the range from 0° to 10°. In addition to full sample rotation, the programmable rocking angle control is ideally suited for preparing cross-section samples.

Improving the sample surface

Ion milling is used in the physical sciences to enhance the quality of the sample surface. Inert gas, typically argon, is ionized and then accelerated toward the sample. By means of momentum transfer, the impinging ions sputter material at a controlled rate.

Advanced ion source technology

Two TrueFocus ion sources direct controlled-diameter ion beams to the sample regardless of energy. The unique design of the TrueFocus ion source allows adjustable beam diameters. When operated in the upper energy range (up to 6.0 keV), milling is rapid, even at low angles. When operated at low energy (as low as 100 eV), material is gradually sputtered from the sample without inducing artifacts.

Programmable, automatic operation

The SEM Mill operates with minimal user intervention. It features a modular design for basic instrument operation or fully automated control. The universal control platform manages total instrument operation. The basic version of the SEM Mill is for users who require only primary level instrumentation function. The premium version adds full computer control for setting, operating, and recording a broad variety of instrument parameters. Ion milling is automatically terminated at the end of the programmed time.

Enhanced viewing

The SEM Mill accepts a stereo microscope to enhance sample viewing. The microscope's long working distance allows the sample to be observed in situ while milling. The SEM Mill can be configured with an imaging system including a high magnification microscope coupled to a CCD camera and video monitor to capture and display images.

Model 1060

Model 1060