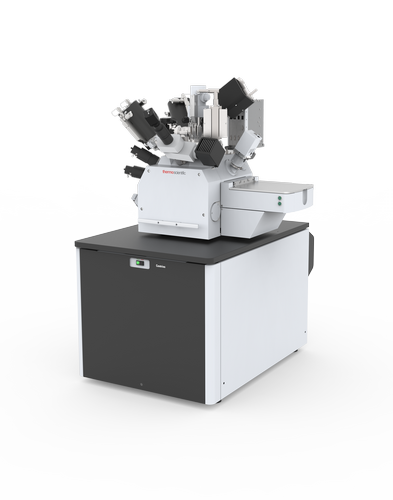

Centrios Circuit Edit System

Semicondutor debug, repair and rapid prototyping.

| The Thermo Scientific Centrios Advanced Circuit Edit System enables rapid prototyping and first silicon debug and repair for 14 nm and above design rule devices. It enables advanced front and backside edits with unparalleled editing control and precision. Using an innovative simultaneous dual nozzle gas delivery system, with the broadest portfolio of chemistries and the latest FIB technology, the Centrios System offers fast, efficient, and cost-effective editing on advanced integrated circuits for reduced time to market. When circuit edits require precision, but the market wants it fast, the Centrios Advanced Circuit Edit System helps meet the demands of the high-tech world. The new Centrios System enables high-performance front and backside edits on advanced integrated circuits for 14 nm and above design nodes with unparalleled precision. Cost-cutting and time-saving gas delivery system maximizes precision and control. An innovative simultaneous dual-nozzle gas delivery system offers precision etching, reducing circuit design costs for faster time to market. | |

Key Features

Imaging and milling resolutionUsing field-proven Thermo Scientific Tomahawk WDR FIB technology with latest beam profile improvements. Dedicated circuit edit focused platformIntegration of key components, such as gas chemistry delivery, enables optimized manual and automated applications. | Enhanced milling precision and controlPlanarity/uniformity, delayering/etch stopping and high-acuity drilling of high-aspect-ratio vias using simultaneous dual-nozzle gas delivery system and proprietary gas chemistry portfolio. Lower cost of operationThermo Scientific NEXS CAD software for navigation and Thermo Scientific iFAST software enables customized automation to improve efficency and ease of use. | |

For more details: https://www.thermofisher.com/tr/en/home/electron-microscopy/products/circuit-edit-systems/centrios.html